R&D Center

| R&D Center |

|

Technology Development The Center for Technology Development develops and supplies various technologies to improve core technology, improve quality, and improve the efficiency of painting facilities. |

Development field

|

|

|

|

| 2D / 3D Robot Vision System | 3D SCAN Vision System |

Surface Inspection System | Technical patent |

Development Performance

|

|

|

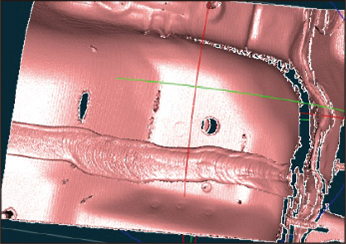

Development of AITZ 3D SCAN VISION Products

- Precision 3D Scan Vision System Using Beam Module and Industrial Camera

- Apply groundbreaking noise rejection technology

- Convenient User-Interface feature

- Simple and stable pattern matching

|

|

|

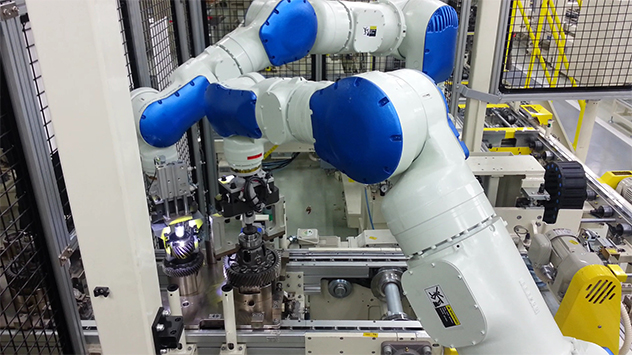

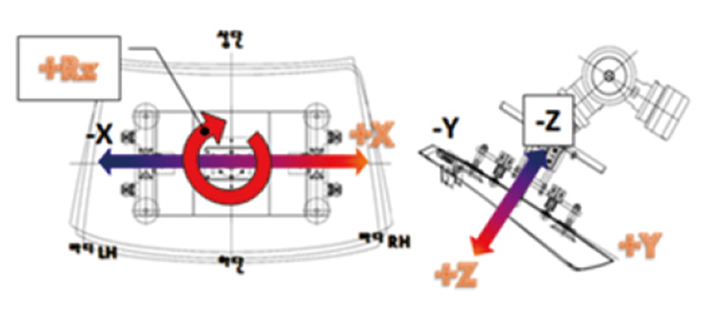

3D robot positioning technology using stereo visual sensors and LED lighting.

- Accurate three-dimensional shape recognition using a four-set strain camera.

- Multiple vehicle models can be processed on one production line.

- If one of several robots fails, the remaining robots can perform the task.

|

|

|

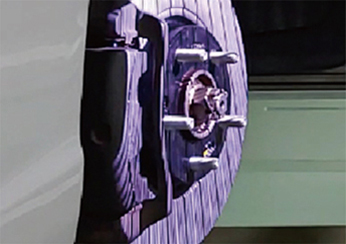

Paint surface inspection system

- Development of an inspection system that detects defects in the paint surface of the body and allows the robot to perform marking in the defective position by interlocking the coordinate system of the body.

|

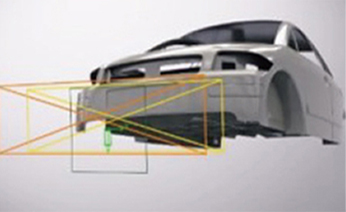

Measurement and Calibration System for Gap Deviation in Vehicle Glass Mounting Process

- A technique for measuring gaps and gaps in the glass installation process using laser sensors and camera vision.

- Develop an algorithm to correct robot gripper position and posture information that performs glass installation using error information of measured values relative to gap/short reference values.

|

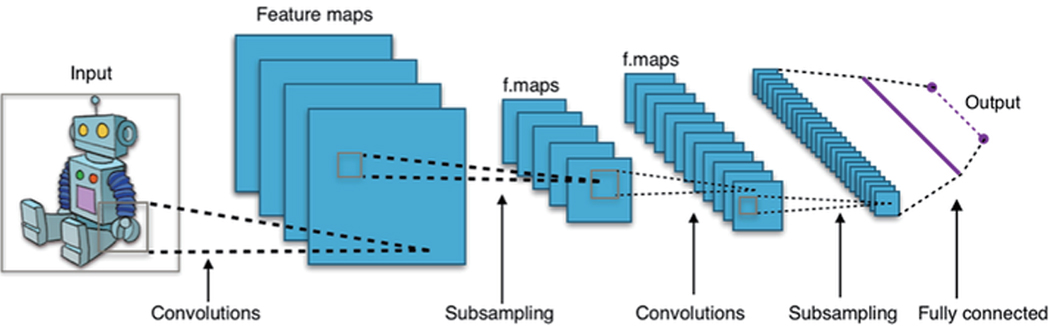

Deep learning

- Deep learning is a technique used to cluster or classify objects or data.

- Based on artificial intelligence, it provides functions comparable to human visual inspection.

- High accuracy and fast processing speed through the application of CNN, which shows outstanding performance in image processing.

|

|

|

Industrial black box

- It is mounted on a robot in an automated process to record and store robot movements to check for abnormal robot movements.

- In the event of an accident, the cause of the accident can be identified through the robot's driving video.

- Image monitoring and video download are possible via high-sensitivity WIFI and TCP/IP communications and HDMI connections.

- I/L interface via IO module is printed on the image screen to make it easier to identify the cause of an accident.

|

|

|

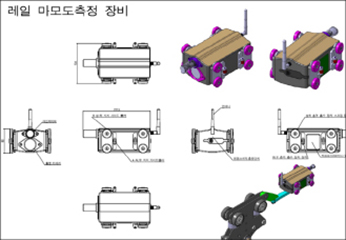

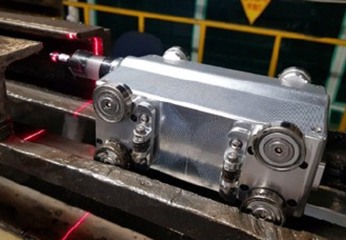

Rail Wear Inspection System

- It is installed with an OH rail and operated together, so that the degree of wear of the OH rail can be directly checked and the degree of wear can be measured through vision measurement to determine abnormalities.

- Using the deep learning algorithm to measure the expected frame of the problem and to improve detection rate through classification and learning through a lot of image information.

- Interframe motion detection algorithm identifies the measurement location of the filming rail.